|

Graftex® must by applied by qualified and certified installers, under the supervision of Protection Hydrofuge.

The product must be applied in conformance with the manufacturer`s installation manual, dated 4th January 2010.

To get the PDF file, click here.

TECHNICAL NOTICE

Type |

GRAFTEX CCMC 13023 is a colourless waterproofing treatment for exterior and interior use based on a 100% acrylic emulsion and Teflon® from DuPont.

|

Areas of application

|

It ensures the protection of mineral supports like concrete, against

carbonatation and the ravages of chemicals (acid rain, deicing salt),

water, frost, micro-organisms and graffiti.

|

General Properties

|

• Colourless, it doesn’t alter the appereance of the supports

• Resists chemical attacks from atmospheric pollution

• Very high resistance to carbon dioxide diffusion

• Permeability to water vapour: 198 g/m2/24 hours

• Water repellant

• Non polluting aqueous (water-based)

• Protect against erosion

• Resists alcalis

• Resists UV rays

• Has anti-soling and graffiti protection properties

• Conforms to Masterformat section 07191 of the CNRC

|

| Physicals Properties |

• density at 20ºC:

• Solids by weight (dry):

• coverage:

• viscosity at 20ºC:

• Gloss mat:

• drying time:

• resistance to diffusion:

• packaging:

• storage: |

1.025 - 1.050

31% - 34%

5 to 10 m2/L

300 to 400 mPa.s

10 Gardner scale at 60ºC

15 to 60 min. depending on the weather condition (humidity)

u CO2 = 3,400,000

SD 40 = 136 m

u H2O = 4,850

SD 40 = 0.19 m

16 L in 20 L can

Store where protected from freezing

|

| Application data |

Spray with airless tip 413 or 415, roller, brush. |

FIELD OF APPLICATION

The measurement of water absorption under low pressure is a test that may be useful when it comes to:

- Assessing the range of certain types of degradation of stone in situ.

- Determining the importance of the pores filled by an impregnation treatment.

- Assessing the success of a waterproof treatment.

- Assessing the durability of a treated stone.

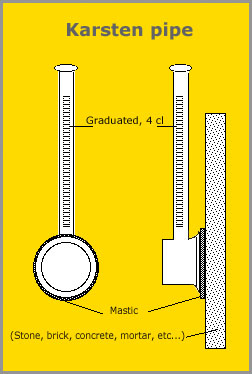

| Water absorption test

Surface porosity is determined in situ with the help of

an absorption pipe.

The pipe consists of a tube graduated to the tenth of a

millimeter. Water absorbed by the material can then be

quantified as the level of the water in the tube

diminishes after 5, 10, and 15 minutes.

Measures are taken at a initial water pressure of

92 mm which corresponds to a static wind at 140 km/h

calculated through the following equation

Q (kg/m2) = V2 (m/s)/16

The height of the column of water in millimeters

corresponds to the pressure (kg/h) exerted by the

water whereas 1mm of water corresponds to 1 kg/m3

V = speed of wind corresponding (m/s). |

Examition method

Karsten-pipe(tube) |

Testing apparatus (equipment): Type A - for vertical

surface, sealing material, plasticine and water.

Remark: The examination method cannot be used

for strongly structured surface due to problems with sealing.

Execution: Glue the examination pipe on with plasticine.

Put ring-shaped sealing material around the contact surface of the

glass tube. Press to the area and seal with additional plasticine

from outside. No water is allowed to flow out of the sealing. Fill

the tube with water until the mark of 4 milliliters.

First, check after 5 minutes of waiting time. Then check the difference

between the filling amount (4 milliliters) and the new scale mark.

WAC 5' = Water absorption coefficient at 5 minutes

Second of all, check after 15 minutes as described above. |

| Evaluation |

Determine the waste-water in milliliters.

(e.g.: 0.2 ml for WAC 5' and 0.5 ml for WAC 15') |

|

Calculation |

WAC = WAC 15' minus WAC 5'

For example above: 0.5 ml minus 0.2 ml = WAC 0.3 ml

For a good hydrophobic effect of the covering, the WAC result must

not be higher than WAC = 0.3 milliliter.

The difference of absorption between the measurements observed

at

5 and 15 minutes (E.15 - 5) gives the degree of absorption quasi

independently of the initial statistic of humidity of the support

under

going testing.

|

| Remarks

|

° Perform a Karsten pipe test on each façade.

° Determine the orientation of the facades (North, South, East or West)

° Certain plasticines can leave marks if they are used on surfaces exposed

directly to the sun.

° For stone and brick, Karsten pipe tests should be performed on the

mortar as well.

|

| Preparing the substrate |

° The substrate must be clean and free of dust, grease, soot, mould and

micro-organisms.

° Moss, cryptogams, etc. must be destroyed with an anti-cryptogamic

solution before applying Graftex®.

° Check seal of window frames, roof, chimney cap, eaves troughs, etc...

If necessary, make any necessary repairs.

° Window sills made of brick must be covered with aluminium or another

similar material.

° Clean out and rejoint brittle and degraded joints. Repair cracks,

fissures and other defects.

° For repairs requiring mortar, wait 1 week before waterproofing. |

| Moistening the substrate

|

Before applying Graftex® on substrates, they must be moistened, as this helps the product penetrate, improves its performance and prevents the formation of thick spots. Spray water on the substrate with a hose or high pressure washer. Once the substrate has absorbed the water, apply Graftex® on the still-damp substrate. The substrates to be treated with Graftex® must be kept continuously damp.

|

| Waterproofing the substrate |

Mix the product well, preferably mechanically, before applying it.

Graftex® can be applied with an airless spray gun (use nozzle tip 413 or

415 with a 213 angular), a roller or brush.

Brushes and rollers: use a roller to apply it to smooth surfaces,

such as concrete.

Use a spray gun, preferably, for rough surfaces. If this is not possible, apply the product with a roller and remove excess with a whitewash brush.

Applying too thick a coat on material, whether damp or not, may lead to the formation of a whitish deposit. The same phenomenon may result from drips and laps, which can be eliminated with a dry brush or roller before drying. |

Consumption

* Given that some brick can absorb up to 3,200 g/m2, or even more, in an hour, it would be preferable

to consult us when using the product in such situations. |

If diluted with 50% water, do not moisten the substrate; moistening a must however for other applications.

| Example of application |

CONCRETE

The first coat of Graftex® must always be applied on damp concrete.

Let dry for approximately 60 minutes before applying the second coat.

For good prevention of carbonation, plan to use roughly 100 g/m2 per coat.

|

| Procedure for treating brick |

° Use a spray gun for best results. If this is not possible, apply Graftex®

with a roller; once you have a clear coat, remove drips and excess

product with a whitewash brush.

|

(for 20% dilution with water) |

° Apply 2 coats of Graftex® diluted 20% with water. |

| Drying time |

15 to 60 minutes depending on the weather conditions (temperature, humidity, wind) and the porosity of the materials being protected.

|

| Protection against graffiti |

Method for removing graffiti

Remove with hot (80° to 90°C) water in a high-pressure jet (approximately 80 to 100 bars, depending on the hardness of the substrate).

After removing the graffiti, the substrate will be bare and must be reprotected as follows:

-1st coat of Graftex® diluted with 20% water, on a damp substrate

-2nd coat of Graftex® undiluted, on a dry substrate.

|

| Cleaning application equipment |

° Rinse equipment with water immediately after use. If you will not be

using the spray gun again for a while, immerse in water.

° Rinse away spatters on doors, windows, shrubs, aluminium, etc. with

clear water immediately.

|

| Remarks |

° Do not apply product when the ambient temperature and/or the

temperature of the substrate is below 5°C, or the humidity is above 90%.

° Do not apply in direct sunlight when sun is at its strongest.

° Store where protected from freezing. |

If in doubt, contact us.

|